Johnson Shop Manuals

The Johnson-Evinrude Workshop manual downloads for the above listed models describes the service procedures for the complete vehicle. Follow the Maintenance Schedule recommendations to ensure that the outboard is in peak operating condition.

Raising Capital 16. Working Capital Management 14. Risk and Return Part 3: Capital Budgeting 9: Capital Budgeting Decision Models 10: Cash Flow Estimation 11: The Cost of Capital Part 4: Financial Planning and Evaluating Performance 12. Forecasting and Short-Term Financial Planning 13. Financial management core concepts 3rd edition pdf. Financial Ratios and Firm Performance Part 5: Other Selected Finance Topics 15.

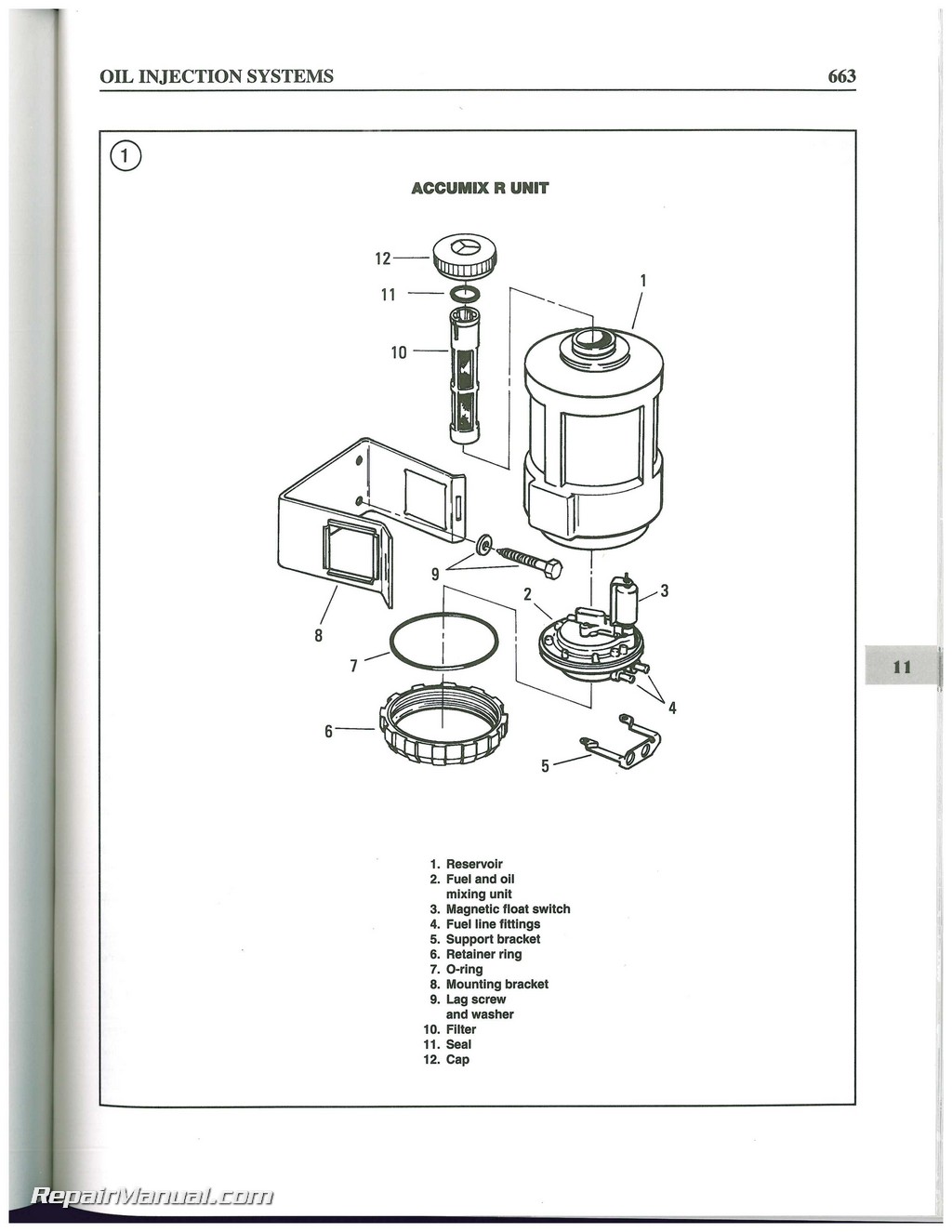

Performing the scheduled maintenance is very important. It compensates for the initial wear that occurs during the life of the outboard motor. All chapters in the Workshop Manual apply to the whole vehicle and illustrates procedures for removal/installation of components that are in detailed step-by-step fashion. Most all Workshop manual chapters start with an assembly or system illustration, diagrams, exploded parts view, pictures, service information and troubleshooting for the section. The subsequent pages give detailed procedures.

Johnson Outboard Shop Manuals

PROBLEM 1: ENGINE TURNS OVER BUT WILL NOT START OR STARTS HARD WHEN COLD Possible Cause Corrective Action Improper starting procedure. Check procedure, as outlined in “Operation and Maintenance Manual.” Fuel tank empty; improperly mixed fuel; contaminants (water, dirt, etc.) in fuel. Check fuel in fuel tank and replace or add.

Fuel tank air vent closed or restricted. Air vent must be open and free from contaminants. A pinched or restricted fuel line.

Check, and replace as needed. Dirty or restricted fuel filter. Check, replace or clean. Enrichener valve not operating.

Check enrichener system. (Refer to “Enrichener System” following.) An inlet needle (in carburetor) that is stuck open or closed. (A needle stuck open, will cause a flooding condition. A needle stuck closed, will prevent fuel from entering carburetor.) Remove, clean, or replace. Anti-Siphon valve restricting fuel flow. Refer to “Checking for Restricted Fuel Flow caused by Anti-Siphon Valves”, following. See “Checking for Restricted Fuel Flow caused by Anti-Siphon Valves”, page 3A-1.

PROBLEM: ENGINE FLOODS Possible Cause Corrective Action Dirt or foreign particles are preventing inlet needle from seating. Flush out inlet seat and clean inlet needle. Worn inlet needle. Punctured float. Incorrect float setting. PROBLEM: ENGINE RUNS TOO LEAN Possible Cause Corrective Action Carburetor is loose. Air leaks past mixing chamber cover.

Tighten bolts securely. Tighten cover or replace gasket. Fuel level too low. Reset float level. Clogged high speed jet.

Check and clean. Restricted fuel flow to carburetor. Check fuel lines and filter(s) for restricted flow. Incorrect high speed jet. Refer to main jet chart and replace with proper jet.

Idle mixture set too lean. Adjust to run richener. Air leakage into fuel system. Check fuel line connections, hose clamps, fuel pump, and fuel outlet tube (located in fuel tank) for loose fittings. Anti-Siphon valve restricting fuel flow. Refer to “Checking for restricted fuel flow caused by Anti-Siphon valves.” PROBLEM: ENGINE RUNS TOO RICH Possible Cause Corrective Action Fuel level too high. Reset float to correct level.

Carburetor floods. See preceding “Engine Floods” Idle nozzle air holes plugged. Blow out with compressed air. Restricted air flow. Check cowl air inlet and carburetor for obstructions. Main Fuel Jet loose.

Retighten Jet. PROBLEM 1: ENGINE IDLES ROUGH AND STALLS PROBLEM 2: ENGINE RUNS UNEVEN OR SURGES PROBLEM 3: ENGINE WILL NOT ACCELERATE Possible Cause Corrective Action Fuel tank air vent closed or restricted. Check - Air vent must be open all-the-way and free from restrictions. A pinched, cut or restricted fuel line; also loose fuel line connection.

Check all fuel lines and replace as needed. Check and tighten all fuel line connections. A dirty or restricted fuel filter. Check, replace, or clean all fuel filters. Restricted filter in fuel tank. Clean by rinsing in clean lead-free gasoline or kerosene. Improperly mixed fuel; contaminants (water, dirt, etc.) in fuel.

Check fuel and replace, if necessary. An inlet needle (in carburetor) that is either stuck open or closed. (A needle, that is stuck open, will cause a flooding condition. A needle, that is stuck closed, will prevent fuel from entering carburetor.) Remove and replace with new inlet needle. Incorrect idle mixture adjustment.

Damaged fuel pump diaphragm. Carburetor is loose. Tighten bolts securely. Chamber cover leaking air. Tighten or replace gasket. Off idle holes plugged.

Blow out with compressed air. Main nozzle or idle nozzle air bleed holes plugged.

Blow out with compressed air. Improper main jet or restricted jet. Clean or replace with proper jet (refer to “Main Jet Chart”). Damaged reed(s). Inspect reeds as outlined in Section 4A.

A crack in the fuel pick-up outlet tube (located in fuel tank). A crack in the fuel outlet tube (located in fuel tank.) Replace.

Anti-Siphon valve restricting fuel flow. Refer to “Checking for Restricted Fuel Flow Caused by Anti-Siphon Valves,” following. PROBLEM: FUEL BLOW-BACK OUT OF CARBURETOR Possible Cause Corrective Action Chipped/Broken (reed-block) Reeds Replace Reeds. PROBLEM: ROUGH IDLE If related to reed-block, indicates excessive preload in reeds. Replace Reeds.

PROBLEM: CAN’T REDUCE ENGINE RPM TO SLOW IDLE Multiple Chipped Reeds. Replace Reeds. Checking for Restricted Fuel Flow Caused by Anti-Siphon Valves While anti-siphon valves are helpful from a safety standpoint, they clog, they may be too small, or they may have too heavy a spring. The pressure drop across these valves can, create operational problems and/or powerhead damage by restricting fuel. Some symptoms of restricted (lean) fuel flow, are: 1. Loss of fuel pump pressure 2.

Loss of power 3. High speed surging 4. Preignition/detonation (piston dome erosion) 5. Outboard cuts out or hesitates upon acceleration 6.

Betsey Johnson Shop

Outboard runs rough 7. Outboard quits and cannot be restarted 8. Outboard will not start 9. Vapor lock Any type of anti-siphon device must be located between the outboard fuel inlet and fuel tank outlet. A method of checking if such a device (or bad fuel) is a problem source is to operate the outboard with a separate fuel supply which is known to be good. If, it is found that the anti-siphon valve is the cause of the problem, either 1) replace the anti-siphon valve or 2) replace it with a solenoid-operated fuel shutoff valve. 1973 1990 Johnson Evinrude 2 to 40 HP Service Manual Outboard Johnson - Evinrude Service Manual Application: 1973, 1974, 1975, 1976, 1977, 1978, 1979, 1980, 1981, 1982, 1983, 1984, 1985, 1986, 1987, 1988, 1989, 1990 Outboard For 2, 2.5, 4, 4.5, 5, 6, 7.5, 8, 9.5, 9.9, 15, 18, 20, 25, 28, 30, 35, 40 HP (Horsepower - Horse Power) Outboards Marine Engine Johnson/Evinrude 2Stroke 2-Stroke Two Stroke & 4Stroke 4-Stroke Four Stroke models.

Jermaine Funnymaine Johnson Shop

1973-1990 Johnson Evinrude Service Manual 48 235 HP Outboard & Sea Drives Johnson - Evinrude Service Manual Application: 1973, 1974, 1975, 1976, 1977, 1978, 1979, 1980, 1981, 1982, 1983, 1984, 1985, 1986, 1987, 1988, 1989, 1990 Outboard & Sea Drive (Sea Drives) For 48 50 55 60 65 70 75 85 88 90 100 110 115 120 135 140 150 175 185 200 225 & 235 HP (Horsepower - Horse Power) Outboard & Sea Drive Marine Engine Johnson/Evinrude 2Stroke 2-Stroke Two Stroke & 4Stroke 4-Stroke Four Stroke models.